Illustrated History of Ancient Wine - 1862

So many different causes influence this that hardly two casks of the same sort of wine are precisely equal in all their points. If the wines are filled in barrels or bottles after the must has gone through the first fermentation, and before all the sugar has been dissolved by the after fermentation and the yeast secreted, they will continue to ferment more or less vigorously, and to develop a great deal of carbonic acid, which may burst the casks if quite filled.

The gas rises in a multitude of small bubbles, spouting up when the barrels are opened, in case they withstand the pressure. Such wines are called effervescent. The kind most known of them is the Champagne.

Relics of the Boar's Head

Wine Carafe

Container of Grapes for Wine

On Ancient and Modern Wines

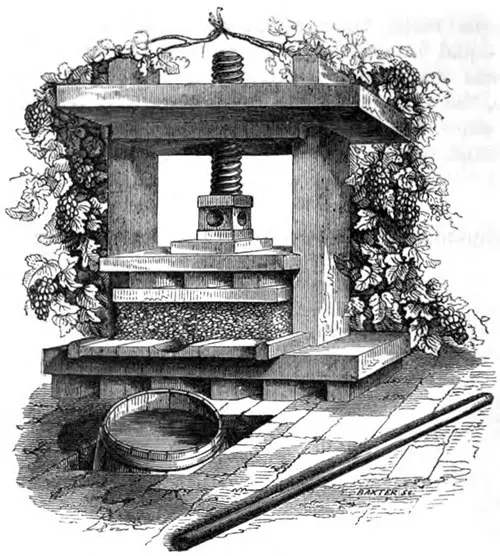

The Smaller Wine Press

The grapes must be passed very rapidly through the wine press, to avoid all fermentation in the berries, and all coloring of the must. The must is not immediately barreled, but left for from twelve to twenty-four hours in vats, so that it may deposit all its coarser dregs; then it is drawn into scrupulously cleaned and sulphured barrels.

Gathering the Grapes

It ought to be a policy always to undertake this only when they have attained their highest state of maturity, as it is well-known that they are the richer in sugar the riper they are, and produce the more alcohol the more sugar parts are contained in them.

Wine Vessels

Symbols of the Vine

Wine Vessels: The Sack Cup is at Cothele, Cornwall

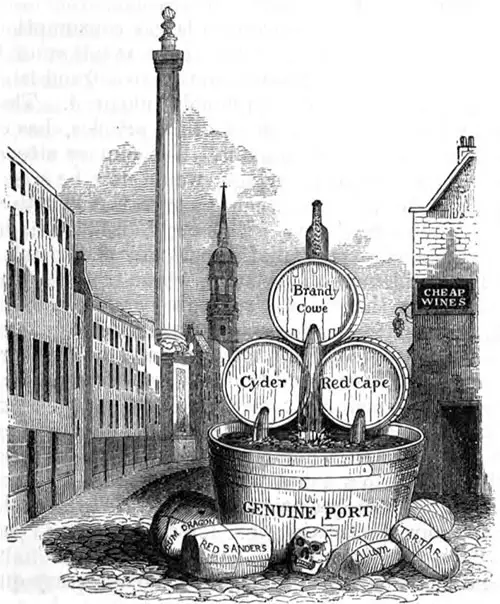

Genuine Wine Manufactory

ILLUSTRATIONS From: Grape culture wines and wine making in 1862

From page 350 onward, there are several diagrams of APPARATUS FOR WINE MAKING. Below are the 2 that I think summarize the making of wine from start to finish.

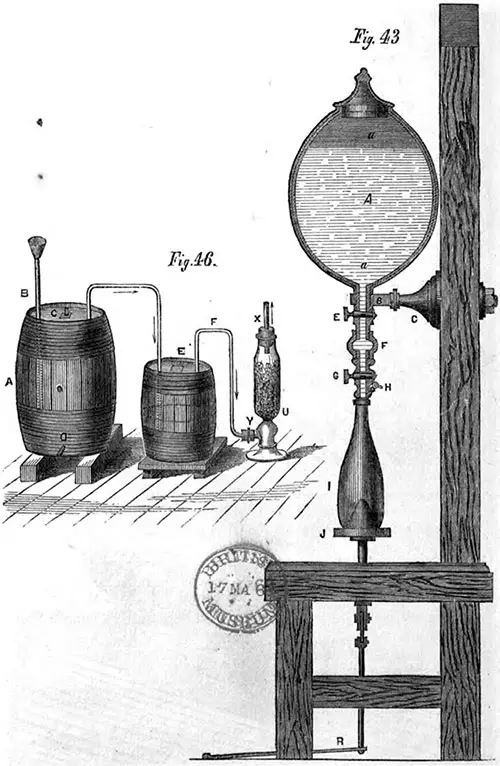

Fig. 46 Apparatus For Wine Making

The cask A is filled with chalk or carbonate of lime (limestone) and water. The opening C is then closed hermetically, and sulphuric acid when chalk, chloric acid when limestone is used, is poured through the leaden funnel B into the cask.

The carbonic acid thus developed is conducted through the pipe D into a smaller cask filled with water, marked E, and from there through another pipe, F, into the glass stand G, filled with small pieces of chalk, which binds the last particles of free acids. Through the pipe X the pure gas is led into the gasometer G (Fig. 45 - Below)

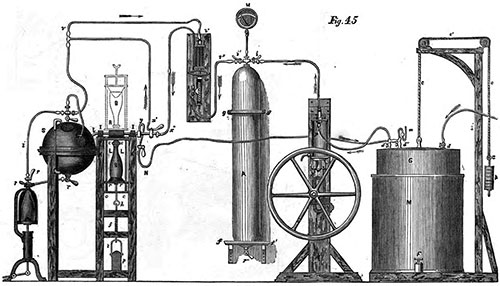

Fig. 45 Apparatus For Wine Making

The following explanation of this apparatus is only for the most hearty of individuals with a keen interest in this ancient process of wine making.

This is a bell-shaped vessel, of tin or tinned copper, which hangs in a vat of the same metal, marked M F, filled with water up to two inches from its margin, and is balanced by the weight P". By turning the stopcock d the gas is conducted into the gasometer, flows through d' into the forcing-pump P, while by a third stopcock, marked d", the gas returning from the vessel S is admitted again into the gasometer. The pipes which connect the different stopcocks are made of India-rubber. The pressure of the gas is measured by a small Manometer, marked m.

By means of the forcing-pump P the gas is driven into the condenser A' through the pipe i. This is a copper cylinder plated with tin, and holds 1 1/2 hectoliters, the sides being from 3 to 4 millimeters thick, in order to have sufficient strength to sustain a pressure of 20 atmospheres, which is the amount of gas required for one day’s work. The condenser rests on a board, marked f f'' and is fastened to the wall by means of an iron ring g y, wound round with rope, and is furnished with a stopcock, marked r", which serves to let off the water that gathers in the cylinder. The atmospheric pressure is measured by the Manometer M.

Through the pipe i' t" r' the carbonic acid is let into the vessel S, and the pressure regulated in the following manner : The pipe v' v" conducts the gas into a cylinder of India-rubber one centimeter thick, which is closed by two round pieces of the same material, fastened to bronze plates, one of which is fixed, while the other is movable, and is pressed down by the gas putting in motion the pieces z and y, the teeth of the latter piece, turning the wheel, gradually closing the stopcock r', through which the gas is let into the vessel S.

By the elasticity of the India-rubber and a spiral wire which is wound round the cylinder, the plate is drawn back, and so the stopcock opened again; and by this alternate opening and closing of the entrance to the vessel S, the pressure is regulated. To still increase the power of the regulator, a spring, Z, is attached to the movable bronze plate.

The Vessel S (Fig. 45). —By pressing down the treadle p, the piece f which is furnished with a spring, is pulled down, which moves the ring A, to which the piece k is attached, so lowering the stand d d on which the bottle is placed. On releasing the treadle, the springs r r presses the bottle against a circular piece of India-rubber in the middle of c c. Take now the plateau c c, move it forward so as to turn it over the body K of the stopcock, which forms part of the upper plate c c; thus the frame c c, c' c' is brought in the position indicated by the punctuated lines, and the bottle is in B. After this semicircular motion, the gas in the interior of the bottle is balanced by that in the interior of the ball S.

Cyrus Redding, A History and Description of Modern Wines, Third Edition, with Additions and Corrections, London: Henry G., Bohn, 1851.

A. Haraszthy, Wines, and Wine-Making: With Notes Upon Agriculture and Horticulture, With Numerous Illustrations, New York: Harper & Brothers, 1862.