The Birth of Freshness: How Vacuum-Sealed Coffee Revolutionized the Industry in 1921

📌 Explore the groundbreaking 1921 coffee-roasting plant that revolutionized coffee storage, freshness, and distribution. Learn how vacuum-sealed tins preserved coffee’s original flavor, setting the foundation for modern gourmet coffee packaging. A must-read for epicureans, coffee historians, industry professionals, and food science enthusiasts! ☕🏭

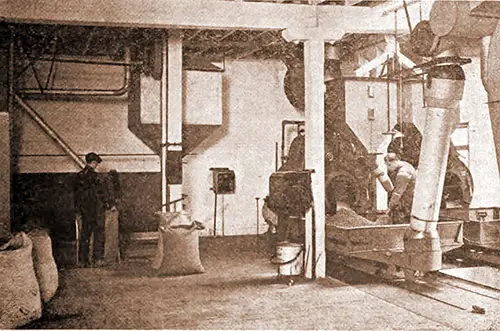

The Vacuum-Packed Coffee Comes in This Way To the Second Story. An Outer Slip Cover Is Put by Hand on the 1-Pound Tins, Which Then Go in 30-Tin Containers. The Upper End of the Conveyor Is Shown in Fig. 3. The Spice Mill, December 1921. | GGA Image ID # 1637c51a17

☕ The Modern Coffee-Roasting Plant (1921): A Revolutionary Leap in Coffee Preservation & Packaging

🔎 A Deep Dive into Coffee Roasting, Vacuum Sealing, and the Industry’s Future

The 1921 article on modern coffee-roasting plants unveils a pivotal moment in the history of coffee production—the transition from bulk coffee sales to vacuum-sealed packaging, ensuring longer shelf life, quality preservation, and consistent flavor. This was a game-changing development that not only reshaped coffee distribution but also transformed consumer habits, making fresh, high-quality coffee more accessible across the United States and beyond.

For epicureans, food historians, teachers, students, and industry professionals, this article provides a fascinating historical perspective on technological advancements in coffee preservation—a crucial step toward the modern gourmet coffee experience we enjoy today.

About a year ago, this modern coffee-roasting plant was established at Buffalo to market specially packed coffee in the United States, such as the Dalley Products Company, in Hamilton, Ontario, has been selling for several years.

The Canadian business is an old one. Originally, it included various other food products, which were all given up as the special coffee business developed. H. C. Cosby, long in charge of coffee operations in Hamilton, is also the manager of the Buffalo business.

The particularly interesting feature of this Buffalo plant is the equipment for putting the coffee, after the most careful roasting and grinding, in special tin cans. These cans are finally closed automatically inside a vacuum chamber to permit every remnant of air to be drawn out of the package before it is sealed.

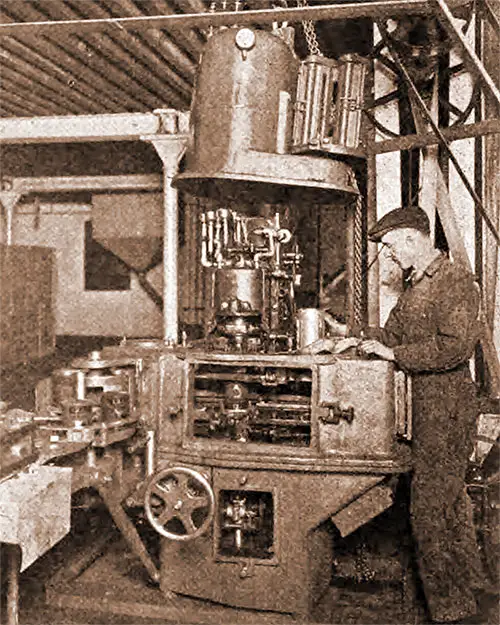

The Vacuum-Sealing Machine, Opened for Inspection. the Filled Tins Are Automatically Carried in From the Conveyor on the Left and Are Closed and Sealed As They Circle Around the Vacuum Chamber. the Next Image Shows the Delivery Point. The Spice Mill, December 1921. | GGA Image ID # 1637d7ac2e

Packaging operations have been employed with great success for many other food products. They are now making real headway in the roasted coffee field.

Vacuum-packed coffee was first introduced on the Pacific coast, particularly to meet the needs of an important market in Alaska, where very bad delivery conditions prevailed.

This method of packing proved so successful for Alaska trade that it seemed worthwhile for customers nearer home, who frequently had to buy their preferred brand of coffee a long time after it had been roasted.

So, the original users of the vacuum-sealing process for far-away trade began to use it also for the general distribution of their high-grade goods, and other houses soon followed suit.

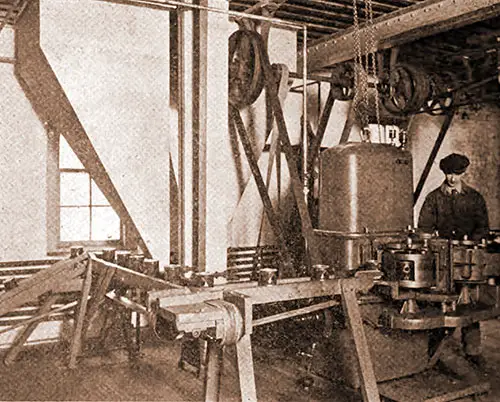

Delivery of the Tins From the Vacuum-Sealing Machine. The Large Suspended Bins Hold Granulated Coffee, Which Is Carried by the Bucket Elevator up to the Fourth Story for Transfer to the Weighing Machines. The Spice Mill, December 1921. | GGA Image ID # 1637e04a72

It is stated that the amount of coffee packed by vacuum-sealing machines in Pacific coast territory during the year 1920 amounted to nearly 24,000,000 pounds or a little more than 25 percent of all the coffee roasted in that section and that the proportion has increased to 35 percent at present.

Additional Eastern firms have now adopted the process, and its advantages are being studied by the trade in all parts of the country. Figures from the West Coast state that:

About 53 percent of the vacuum-sealed tins used there are of 1 lb. size;

- 25 percent, 2 1/2 lb. size;

- 12 percent, five lb.;

- 6 percent, two lb.;

- 4 percent, three lb.;

- 1 percent, 1/2 lb.

Undoubtedly, there is nothing more significant interest in the coffee trade than correct packing methods. The substantial increase in the wholesale distribution of packaged coffee in recent years is in line with the development happening in connection with all sorts of food products.

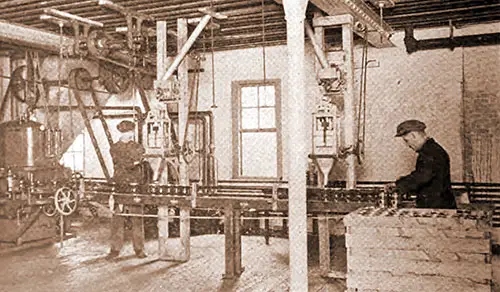

The Weighing Machines, Supplied by the Inclined Spouts From Feed Bins in the Fourth Story, Fill the Tins Which Are Carried by the Conveyor To the Vacuum Sealer at the Left. The Spice Mill, December 1921. | GGA Image ID # 1637e456c9

Success in this direction, compared with selling coffee in bulk, depends significantly on the attractiveness of the general package idea, which has been fostered by much advertising.

But complete success is vitally related to two important considerations: first, the coffee should always be of uniformly high cup quality when put in the package, and second, the packing method should be able to maintain this quality until the goods reach the consumer.

The claim made for the vacuum—sealed metal package is that it preserves the original cup value of the coffee indefinitely. If this is true, it permits a complete argument to be made for packaged coffee as compared with coffee sold in bulk.

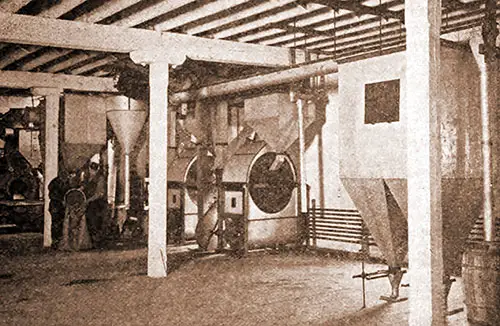

The Weighing-Machine Feed Bins on the Right Are Supplied by an Overhead Conveyor Connected to the Elevator Between the Two Large Granulators. The Workers Are Emptying a Can of Chaff Collected From the Cracked Coffee Before the Final Granulation. in the Background, You Can See the Roasting Equipment. The Spice Mill, December 1921. | GGA Image ID # 1637ed36da

Even in the case of quick local distribution, with every "fresh roast" argument, it is difficult these days to convince users that the quality of bulk goods is as likely to be as uniformly maintained as that of a brand that goes into consumer-size packages as part of its regular preparation for the market.

A packaging method that perfectly preserves coffee goodness seems hardly open to any objection except that of costing too much. And what "too much" may mean must depend in every case on the additional value, from a sales standpoint, which the package itself adds to the product.

On the Left, Green Coffee Is Being Dumped Into the 20-Bag Mixer. on the Right, a Batch Has Just Been Discharged From the Mixer’s Discharge Bin. at the Extreme Right, the Cooled Coffee Floor Hopper Spouts Into an Elevator Feeding the Cracking Granulator. The Spice Mill, December 1921. | GGA Image ID # 1638304fb6

The accompanying pictures and captions give a good idea of the Vacuum packing procedure in the Dalley plant and also show the convenient way all the preceding operations are connected, with ample bins for intermediate storage, so that the desired results can be obtained with the least running expense.

This Buffalo factory is a four-story brick warehouse on Addison Place between Bond and Lord. Of course, the roasters are located in the top story. Also on the top story are a 20-bag green coffee mixer and coffee granulating machinery, together with complete auxiliary appliances partly extending into the lower floors.

"Plant of Dalley Products Company, Buffalo, NY: Producers of High-Grade Roasted Coffee--Distributed in Vacuum-Sealed Tins," in The Spice Mill: Devoted to the Interests of the Coffee Tea & Spice Trades, New York: The Spice Mill Publishing Company, Vol. XLIV, No. 12, December 1921, pp. 2164-2167.

🔥 Key Takeaways: Why This Innovation Was Revolutionary

🏭 From Bulk to Vacuum Sealed: A New Era in Coffee Storage

🔹 Before vacuum-sealing technology, coffee was sold in bulk, leaving it exposed to air, moisture, and flavor deterioration.

🔹 The introduction of airtight, vacuum-sealed metal tins extended freshness indefinitely, preserving the original “cup value” of roasted coffee.

🔹 This shift was particularly critical for Alaska trade, where poor delivery conditions made long-term freshness essential.

💡 Why It’s Interesting:

✅ Food historians & researchers will appreciate how vacuum sealing revolutionized food preservation in the early 20th century.

✅ Coffee lovers & industry professionals can explore how packaging methods influenced coffee consumption habits worldwide.

✅ Epicureans & foodies can see how early quality preservation laid the groundwork for today’s specialty coffee market.

🔬 The Science & Engineering Behind Vacuum Sealing

🔹 The Buffalo coffee plant housed a state-of-the-art vacuum-sealing machine, where tins were automatically sealed inside a vacuum chamber to eliminate all air before being closed.

🔹 The process preserved flavor integrity and ensured each cup tasted as fresh as the day it was roasted.

🔹 The multi-story production system used gravity and conveyor belts to maximize efficiency and reduce labor costs.

💡 Why It’s Interesting:

✅ Engineers & coffee manufacturers can study how early mechanized food packaging systems influenced modern production lines.

✅ Science & technology students can explore vacuum’s role in food preservation and why oxygen exposure degrades flavor.

✅ Baristas & café owners can appreciate the origins of long-shelf-life coffee packaging, a technique still used today.

📈 The Growing Demand for Packaged Coffee

🔹 By 1920, 24 million pounds of coffee were vacuum-sealed annually on the West Coast, representing 25% of total roasted coffee.

🔹 This number jumped to 35% in just one year, showing how rapidly vacuum-sealed coffee gained popularity.

🔹 The trend spread nationwide, with Eastern coffee firms embracing the packaging method to enhance product consistency.

💡 Why It’s Interesting:

✅ Business & economics students can study how branding and packaging transformed coffee from a bulk commodity into a marketable retail product.

✅ Retail & supply chain professionals can see how technological advances led to mass coffee distribution and long-term storage solutions.

🖼️ Noteworthy Images & Their Significance

📌 Fig. 1 - The Vacuum-Packed Coffee Arriving at the Second Story

➤ This image provides a rare behind-the-scenes look at early 20th-century coffee processing, showcasing how large-scale production facilities handled packaging operations.

📌 Fig. 2 - The Vacuum-Sealing Machine, Opened for Inspection

➤ This reveals the core innovation of vacuum sealing, demonstrating how air was removed from tins before being sealed to preserve freshness.

📌 Fig. 3 - Delivery of the Tins from the Vacuum-Sealing Machine

➤ The logistical efficiency of this plant is evident, with large suspended bins carrying granulated coffee across multiple floors to reach the final packaging stage.

📌 Fig. 6 - Green Coffee Being Dumped into the 20-Bag Mixer

➤ This image highlights the initial stages of coffee processing, from raw green beans to final roasted products, offering a comprehensive look at coffee production in 1921.

🎯 Final Thoughts: Why This Article Is Still Relevant Today

This insightful 1921 article isn’t just about coffee roasting—it’s about the evolution of food preservation, branding, and distribution. The innovations discussed shaped the way coffee is stored and sold today, making high-quality, fresh coffee accessible worldwide.

✅ For food historians & researchers – It’s a fascinating case study on how packaging technology influenced the food industry.

✅ For coffee lovers & baristas – It reveals how vacuum-sealed packaging preserved freshness long before modern specialty coffee trends.

✅ For business & supply chain experts – It highlights how technological advancements impacted mass production and product longevity.

✅ For students & educators – It provides an engaging historical perspective on how innovation drives industry transformation.

💡 Whether you're a coffee connoisseur, a historian, or a business professional, this article offers a compelling look at a revolutionary shift in coffee culture—one that still impacts the way we enjoy our coffee today. ☕🚀