How Ship Tonnage is Computed: Understanding Gross Tonnage & Its Impact on Maritime Trade

Ever wondered how ships are measured? Learn how gross tonnage is computed and why it matters for shipbuilding, cargo transport, and maritime law. This detailed guide explains how tonnage impacts ship classification, taxation, and global trade!

This Knowledge Is Necessary to Understand Thoroughly Relation Between Cubical and Carrying Capacity

By ROBERT PHILLIPS

All of us who are concerned with shipping are more or less familiar with tonnage terms. However, we may not understand just how tonnage measurements are taken. This is important, especially to those about to construct or otherwise acquire ships, as a clear understanding of our measurement rules will lead to a more thorough knowledge of the relation between tonnage and carrying capacity.

Before any vessel may be registered, enrolled, or licensed, she must be measured by a customs officer, who ascertains, among other things, her gross and net tonnage. The unit of measurement is 100 cubic feet and is known as the ton, which is expressed as the internal capacity of the measured spaces of vessels. By our laws, specific spaces are exempt from measurement, as described further on.

Gross Tonnage

The gross tonnage of a vessel consists of the sum of the following items:

- The cubical capacity below the tonnage deck.

- The cubical capacity of each space between decks above the tonnage deck.

- The cubical capacity of the permanent closed-in spaces on the upper deck is available for cargo or stores or the berthing or accommodation of passengers or crew.

- The excess of hatchways.

- All permanent closed-in spaces situated elsewhere available for cargo or stores, for the crew's accommodation, or for the charts of navigating instruments (except cabins or staterooms for passengers constructed entirely above the first deck, which is not a deck to the hull).

Under-Deck Tonnage

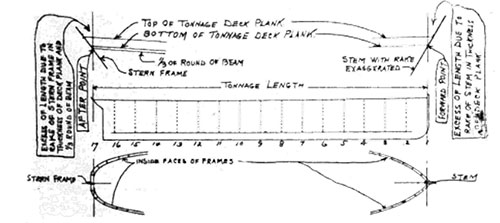

The first step is to ascertain the "tonnage length." The points between which the tonnage length is measured differ from those used to determine the register length. The forward point is at the underside of the tonnage deck plank (or plate in a steel vessel), where the inside of the inner planking meets the side of the stem.

In steel ships with no inner planking, a fair line is drawn around the inside of the frames to meet the side of the stem. The most convenient way to measure the tonnage length is on the top side of the tonnage deck. But as the object of the measurement is to ascertain the cubical capacity under the tonnage deck, and as there may be some rake to the stem, the increased length caused thereby must be deducted.

How this is done is shown in an accompanying sketch.

The after point is where the underside of the tonnage deck planking meets the inside of the inner planking on the stern timbers or frames (or the inside of angle irons or frames in a steel vessel), less the rake of the stem frame to the extent of one-third of the round of the beam at that point. If the length is measured on top of the deck plank, then the rake of the stem timber or frame in the deck's thickness must also be deducted.

The after point is also shown in the sketch. In the case of iron or steel vessels with steel decks, the bow and stern rakes in the deck's thickness are negligible. They may be disregarded altogether, but it must be considered with wooden ships, where the decks are pretty thick.

Tonnage Length

The tonnage length so ascertained is then divided into equal parts as follows:

Under 50 feet, six parts; 50 to 100 feet, 8 parts; 100 to 150 feet, 10 parts; 150 to 200 feet, 12 parts; 200 to 250 feet, 14 parts; above 250 feet, 16 parts.

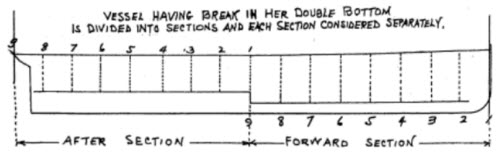

The points dividing the tonnage length according to the above table are to be marked with chalk and numbered consecutively from bow to stern, No. 1 being the extreme forward point. Should a vessel have a break in the line of her double bottom, her tonnage length is to be divided into longitudinal sections by erecting transverse vertical planes at such intervals.

The length of each section will then be divided into equal parts according to the table, just as if it were the length of a separate ship. The tonnage length, having thus been determined and divided into the required number of equal parts, the points of division are transferred to the keelson. This is done by first locating the position of the midship section on the keelson, from which the common interval between the points of division is measured.

Ascertaining Depth

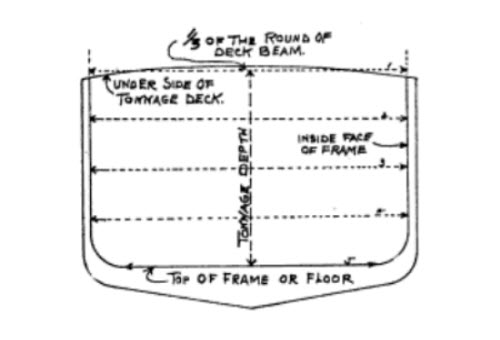

The next step is to ascertain the tonnage depth of the midship section and each other section. The tonnage depth is the distance between a point located one-third of the round of the deck beam below the tonnage dock plank and a point on the upper side of the ceiling, if any, on the floor timbers or frames—otherwise to the upper side of the floor timber or frame—at the inside of the limber-strake.

In case the vessel is constructed with a double bottom for water ballast only, the tonnage depth is to be taken to the upper side of the inner plating of the double bottom, allowing for ceiling, if any, and where vessels have deep double bottoms or deep tanks at the bottom having ordinary floors therein, used other than for water ballast, the depth shall be taken to the upper side of the floors.

If the depth of the midship section is less than sixteen feet, the depth of each section is to be divided into four equal parts—and if it exceeds sixteen feet, into six parts. After the divisions of the tonnage depth are located at each section, the inside horizontal breadth at each point of division (including the upper and lower points) is measured to the inside of the ceiling, average thickness, or, if the ship is not ceiled, to the inside faces of the frames.

Transverse Sections

Now, we are ready to ascertain the area of each transverse section. Where the tonnage depth is less than sixteen feet, and each section is therefore divided into four equal parts, the area is obtained in the following manner.

The breadths are numbered from above. No. 1 is at the top, and No. 5 is at the bottom. Multiply the second and fourth by 4, and the third by 2, add the products, and to the sum, add the first and fifth breadths; multiply the quantity thus obtained by one-third of the common interval between breadths and the product will be the transverse area of the section.

As all measurements are taken in feet and decimals of feet, the areas are in square feet. Where the midship tonnage depth exceeds sixteen feet or where the vessel has a double bottom, there is a slight change in the formula, but the principle is the same.

The hull has been divided into a number of equal sections, and the area of each section is ascertained. To obtain the cubical capacity under the tonnage deck, the areas are combined as follows: The sections are numbered consecutively, beginning at the bow. Multiply the area of the even-numbered sections by 4 and the odd-numbered sections, except the first and last, by 2; these products will be added to the first and last areas.

The sum thus obtained is then multiplied by one-third of the common interval between the sections. The product will be the number of cubic feet below the tonnage deck, which, when divided by 100, will give the under-deck tonnage.

The between-deck tonnage is determined upon much the same principle and then divided by 100.

Spaces on Upper Deck

If there be a break, poop, or any permanent closed-in space on or above the upper or spar deck available for cargo or stores or for the berthing or accommodation of crew or passengers (except the passenger accommodations on a deck not to the hull, exempted by law), the tonnage of such space must be ascertained.

It is found like the method employed in finding the other tonnage, except that the space is divided longitudinally into an even number of equal parts, which must be most nearly equal to the length of the sections of the tonnage deck. The breadths must be taken at the middle of its height.

The cubical contents of the hatchway must be obtained by multiplying the length by the breadth; the product is then multiplied by the mean depth taken from the top of the beam to the underside of the hatch. The whole amount of the hatchway tonnage is not to be added, but only that part of the hatchway tonnage that exceeds one-half of one percent of the ship's gross tonnage, exclusive of the tonnage of the hatchways.

Spaces Exempted

Specific spaces are exempt from measurement but must differ from the deductions to ascertain the net tonnage. Double bottoms for water ballast are not measured; side water ballast tanks extending up from the top of the double bottom wholly or partly to the deck above are likewise exempt.

Spaces under the shelter deck, in the way of the shelter deck opening, are not measured if such spaces in all respects comply with the requirements of the laws. When on or above the upper deck, any space fitted with machinery, the wheelhouse, the galley, bakery, condenser space, toilets, skylights, and companions will not be measured, provided the spaces are no larger than required for the purposes named.

Phillips, Robert, “How A Ship’s Gross Tonnage Is Computed,” in The Nautical Gazette: An International Weekly Chronicle of Shipping, Volume 99, No. 13, Whole No. 2563, New York, Saturday, 25 September 1920, P. 392-393

⚖️ How a Ship’s Gross Tonnage Is Computed: Understanding Maritime Measurement & Capacity 🚢📏

📜 Recap & Summary: The Importance of Gross Tonnage in Ocean Travel & Trade

The article "How a Ship’s Gross Tonnage Is Computed" (1920) by Robert Phillips is an essential resource for understanding how ship tonnage is measured and why it matters for ship construction, registration, taxation, and trade regulations.

This article is particularly relevant for maritime historians, genealogists, teachers, students, ship enthusiasts, and professionals in shipping and trade. It provides a detailed breakdown of tonnage computation, explaining its impact on a ship’s carrying capacity and international regulations.

For teachers & students, it serves as a technical but engaging explanation of ship measurements and naval architecture.

For genealogists, it helps in understanding historical ship records and maritime taxation affecting passenger travel.

For maritime historians, it traces the development of ship measurement laws and their impact on ship design.

For shipping professionals, it clarifies how tonnage is calculated, influencing shipbuilding and cargo logistics.

🔎 Why This Article Matters for Different Audiences

📖 For Teachers & Students

- STEM Education – Explores mathematical and engineering principles in naval architecture.

- Maritime History & Economics – Demonstrates how tonnage affects shipping costs and trade policies.

🧬 For Genealogists & Passenger Researchers

- Passenger Records & Ship Manifests – Many passenger manifests list a ship’s tonnage, influencing immigrant travel conditions.

- Maritime Taxation & Fees – Understanding tonnage laws helps contextualize historical shipping costs and travel documentation.

⚓ For Maritime Historians & Ship Enthusiasts

- Ship Construction & Design – Explains why gross tonnage affects ship size, deck structure, and cargo volume.

- Evolution of Maritime Regulations – Traces the development of measurement standards and their impact on global shipping.

📦 For Shipping & Trade Professionals

- Port Fees & Canal Tolls – Gross tonnage influences cost calculations for ports, canal transits (Panama & Suez), and customs fees.

- Shipbuilding & Design Optimization – Tonnage affects a ship’s legal classification, cargo potential, and financial viability.

📊 Key Topics Covered: The Science of Ship Tonnage & Measurement

1️⃣ What Is Gross Tonnage & Why Does It Matter?

Gross Tonnage (GT) measures the total enclosed volume of a ship, expressed in units of 100 cubic feet per ton.

It is used to register, enroll, or license ships, and customs officers must measure a vessel before official documentation.

Certain spaces are exempt from measurement, such as crew accommodations, machinery rooms, and ballast spaces.

🔍 Why It’s Important: Gross tonnage directly influences a ship’s taxation, port fees, and ability to carry cargo and passengers.

2️⃣ How Is Gross Tonnage Computed?

- Calculate Under-Deck Tonnage – Determine the ship’s length, depth, and sectional volume.

- Measure Enclosed Spaces Above Deck – Include cargo holds, storage, and passenger areas.

- Account for Hatchway Space – Measure hatchway openings exceeding 0.5% of gross tonnage.

- Apply Exemptions – Deduct spaces for ballast, machinery, and accommodations to determine net tonnage.

3️⃣ The Role of Under-Deck Tonnage in Ship Measurement

- Tonnage Length Measurement – The tonnage length differs from a ship’s register length, as it excludes non-cargo-related spaces.

- Depth Calculation – The midship section depth is divided into equal parts for precise volume assessment.

- Transverse Section Areas – A mathematical formula computes the ship’s total internal volume based on sectional area multipliers.

🔍 Why It’s Important: These calculations ensure that ships are classified correctly, preventing tax evasion and optimizing cargo capacity.

4️⃣ How Spaces on the Upper Deck Affect Tonnage

Certain upper deck spaces (poops, bridges, forecastles) are measured if they are enclosed and used for cargo or crew.

Spaces above deck must be divided into equal parts, with measurements taken at the midpoint of their height.

Hatchways are measured separately, but only the space exceeding 0.5% of the gross tonnage is included.

🔍 Why It’s Important: Some ships maximize exemptions to reduce port and canal fees while maintaining high cargo capacity.

5️⃣ Tonnage Exemptions & Legal Considerations

Certain spaces are exempt from measurement, including:

✅ Double-bottom ballast tanks (not used for cargo).

✅ Side water ballast tanks extending up from the hull.

✅ Open shelter deck spaces that meet specific legal conditions.

✅ Machinery rooms, wheelhouses, galleys, toilets, and companionways.

🔍 Why It’s Important: These exemptions reduce taxable tonnage, making a ship more cost-efficient in trade and travel.

📸 Noteworthy Images & Data Diagrams

🖼️ "Tonnage Length Diagram"

✅ Visualizes how tonnage length is measured differently from register length.

✅ Shows why a ship’s structural shape impacts gross tonnage classification.

🖼️ "Diagram for Measuring Gross Tonnage"

✅ Breaks down the process of measuring ship sections into an easy-to-understand format.

✅ Highlights how depth and section divisions contribute to total volume calculations.

🖼️ "Space on Upper Deck"

✅ Illustrates how upper deck areas affect tonnage classifications.

✅ Explains which structures are included in measurements and which are exempt.

🌎 Global Impact of Tonnage Measurement in Maritime Law & Trade

- Shipbuilding & Engineering – Tonnage rules influence ship design, efficiency, and construction costs.

- Economic & Trade Policies – Gross tonnage determines port fees, customs taxes, and international shipping rates.

- Maritime Infrastructure – Ports, canals, and shipyards must adhere to tonnage laws to regulate global shipping.

By understanding how gross tonnage is computed, we gain insight into the foundations of modern maritime trade and shipping economics.

📚 Additional Reading & Resources

📖 "Measurement and Tonnage Laws" – Explores the legal framework behind ship measurement.

📖 "Cargo and Carrying Capacity of Ships" – A deep dive into how tonnage affects cargo transport.

📖 "Net Tonnage of a Vessel and Its Computation" – How net tonnage impacts taxation and trade fees.

These references provide further insights into the evolution of ship tonnage laws and their effect on global commerce.

🔚 Final Thoughts: Why This Article Matters

This detailed guide on gross tonnage computation is essential for understanding how maritime trade and shipbuilding evolved.

🌎 For historians – It explains how ship measurement laws shaped global trade.

📜 For genealogists – It helps decode historical ship records.

🚢 For ship enthusiasts – It offers insights into naval architecture and tonnage classification.

Understanding gross tonnage computation unlocks a deeper knowledge of maritime history, economics, and engineering—making this an essential read for anyone interested in ocean travel and shipping. 🌊⚓