Starcraft American Outboard Runabout Fiberglass Boats (1972)

Before we make Starcraft fiberglass boats beautiful we make them tough.

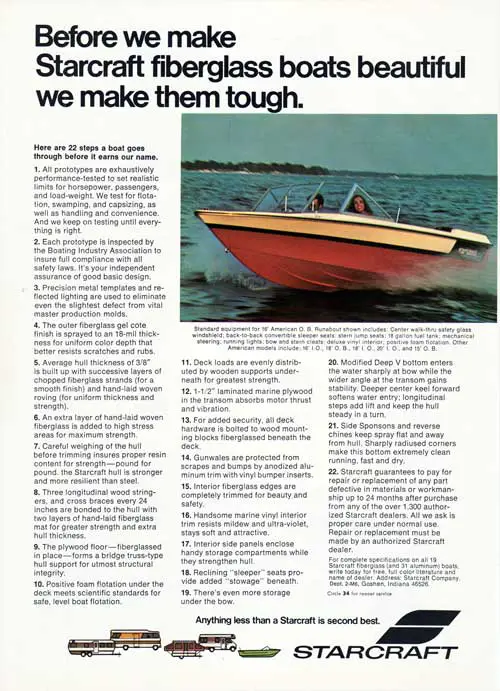

Standard equipment for 16' American O.. B. Runabout shown includes: Center Walk-Thru® safety glass windshield; back-to-back convertible sleeper seats: stern jump seats; 18 gallon fuel tank: mechanical steering; running lights; bow and stern cleats: deluxe vinyl interior; positive foam flotation. Other American models include; 16' I.O., 18' O.. B., 18' I. 0., 20' O.., and 15' 0. B.

Here are 22 steps a boat goes through before it earns our name.

- All prototypes are exhaustively performance-tested to set realistic limits for horsepower, passengers, and load-weight. We test for flotation, swamping, and capsizing, as well as handling and convenience. And we keep on testing until everything is right.

- Each prototype is inspected by the Boating Industry Association to insure full compliance with all safety laws. It's your independent assurance of good basic design.

- Precision metal templates and reflected lighting are used to eliminate even the slightest defect from vital master production molds.

- The outer fiberglass gel cote finish is sprayed to an 18-mil thickness for uniform color depth that better resists scratches and rubs.

- Average hull thickness of 3/8" is built up with successive layers of chopped fiberglass strands (for a smooth finish) and hand-laid woven roving (for uniform thickness and strength).

- An extra layer of hand-laid woven fiberglass is added to high stress areas for maximum strength.

- Careful weighing of the hull before trimming insures proper resin content for strength—pound for pound. the Starcraft hull is stronger and more resilient than steel.

- Three longitudinal wood stringers, and cross braces every 24 inches are bonded to the hull with two layers of hand-laid fiberglass mat for greater strength and extra hull thickness.

- The plywood floor—fiberglassed in place—forms a bridge truss-type hull support for utmost structural integrity.

- Positive foam flotation under the deck meets scientific standards for safe, level boat flotation.

- Deck loads are evenly distributed by wooden supports underneath for greatest strength.

- 1-1/2" laminated marine plywood in the transom absorbs motor thrust and vibration.

- For added security, all deck hardware is bolted to wood mounting blocks fiberglassed beneath the deck.

- Gunwales are protected from scrapes and bumps by anodized aluminum trim with vinyl bumper inserts.

- Interior fiberglass edges are completely trimmed for beauty and safety.

- Handsome marine vinyl interior trim resists mildew and ultra-violet, stays soft and attractive.

- Interior side panels enclose handy storage compartments while they strengthen hull.

- Reclining "sleeper" seats provide added "stowage" beneath.

- Extra Storage There's even more storage under the bow.

- Modified Deep V bottom enters the water sharply at bow while the wider angle at the transom gains stability. Deeper center keel forward softens water entry; longitudinal steps add lift and keep the hull steady in a turn.

- Side Sponsons and reverse chines keep spray flat and away from hull. Sharply radiused corners make this bottom extremely clean running, fast and dry.

- Starcraft guarantees to pay for repair or replacement of any part defective in materials or workmanship up to 24 months after purchase from any of the over 1,300 authorized Starcraft dealers. All we ask is proper care under normal use. Repair or replacement must be made by an authorized Starcraft dealer.

For complete specifications on all 19 Starcraft fiberglass (and 31 aluminum) boats, write today for free, full color literature and name of dealer.

Starcraft Company, Goshen, Indiana 46526.

Anything less than a Starcraft is second best.

STARCRAFT

A Bangor Punta Company

GG Archives REF: BPSTR-017-1972-C-AD