Energy Systems: A Single Source for All Power

Three years ago, on November 9, 1965, a massive power failure plunged much of Northeastern America into darkness. According to the Federal Power Commission, the growing complexity of equipment and increasing use of electric power make blackouts such as this "more probable all the time."

With major power failures increasing nationally to an annual rate of more than 100, many office buildings, hospitals, hotels, motels, apartment complexes and shopping centers are turning to standby generating equipment. At the same time, an increasing number are purchasing "total energy systems" to provide all power requirements from a single in-house source.

Waukesha Motor Company, acquired by Bangor Punta on July 30, 1968, is a leader in the production of engine-generator systems for both uses. The company also manufactures a wide variety of engines which gives Bangor Punta entry into other energy-demanding markets. Waukesha's engines—more than 30 different types and sizes—are operated on diesel, natural gas, LPG (liquified petroleum gas), gasoline, and LNG (liquified natural gas) fuels and range from 13 to 2,200 horsepower.

Waukesha, which constitutes Bangor Punta's Energy Systems group, and is included for two months of the fiscal 1968 year, accounted for 3% of Bangor Punta's total revenues and 2% of profit contribution.

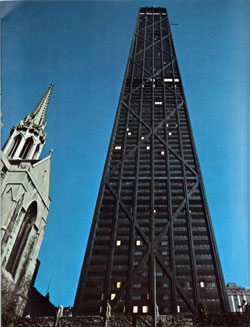

Towering above Chicago's skyline, the new 100-story John Hancock Center is world's tallest apartment-office building. It contains room for 705 apartments and 812,000 square feet of office space. It will consume enough power to serve a city of 30,000 people and its wiring could stretch from the Windy City to Montreal. In case of power failure, Waukesha's standby generating equipment will keep all electric functions humming, including lights, elevators and air conditioning.

With construction spending reaching record levels—$83.5 billion forecast for 1968 by the Department of Commerce—the market for Waukesha standby generating equipment appears to be bright.

In the total energy field, sales of Waukesha's engine-generator power packages, known as ENGINATORS ®, have increased substantially during the past few years. A case in point is Chicago's Sheraton-O'Hare. This large hotel complex now utilizes four high-capacity ENGINATORS® on its premises for all energy requirements. In the process, it has reduced electricity costs by over 50%.

Waukesha engines also continue to gain broad acceptance in the expanding petroleum machinery industry. Here, natural gas and diesel models supply power for a wide variety of tasks—including exploration, drilling, pumping and compressing.

During 1968, Waukesha expanded its new series of diesel engine systems into four major markets: off-highway construction vehicles, the marine industry, standby power generation, and mobile oil field equipment.

To meet growing market needs, Waukesha doubled the size of its O&M Manufacturing Company plant in Houston in 1968 for production of radiators and other heat transfer equipment.

Plans were also announced during the year for the construction of a new 400,000 square foot plant near Waukesha's operations in Wisconsin. The new facilities will provide for manufacture of Waukesha's larger line of engines and turbines, permitting greater production capacity and higher sales and earnings.

Source: Bangor Punta Annual Report for the Year Ended September 30, 1968, Page 12